When people are introduced into the processing chain, they become the slowest link but also the key link. They are required to intervene when automated processing and procedures cannot determine whether a given behavior is correct or not. They control the system by applying their experience and intelligence. They need accurate and relevant information to make the best decision as quickly as possible. Data traceability is therefore essential. Timestamping of data at source can be used to clearly establish the sequence of events. A brief log of measurements taken will provide a better understanding of how the system has changed in a given time period.

Network infrastructure

In a real-time environment, the speed of data transmission is critical. This means, even today, that networks are as important as the actual processes themselves and have to be monitored just as carefully. The communication medium must offer high performance in terms of the area covered by the installation, number of devices connected, throughput, error rate, frame latency, infrastructure robustness and reliability, all of which have to be assessed in relation to the costs of acquiring the data, installation equipment and its maintenance.

Network infrastructure for real-time communications is increasingly using the Ethernet (TCP/IP) standard, especially between PLCs and industrial information systems, as it is capable of meeting many performance criteria. The physical layer is provided by optical fibers guaranteeing consistent speeds and immunity to electromagnetic interference at increasingly attractive prices, and can be easily configured for redundancy. With many different high-level protocols running on the TCP/IP standard, the most suitable one can be chosen for the target devices and types of installation.

Communication protocols

The latest industrial communication protocols focus on interoperability, intelligence and versatility. They are usually secure so there is no longer any need for internal VLAN or VPN. They often make use of secure web services (port configuration, certificate management, etc.) from the world of IT. They can be used not only to exchange data but also to transmit instructions (alarm acknowledgements, etc.), and run procedures (to modify an hourly schedule for instance). However, a modern SCADA system must also offer native management of more conventional PLC style communication protocols (operational technology or OT). It also needs to guarantee OT/IT convergence.

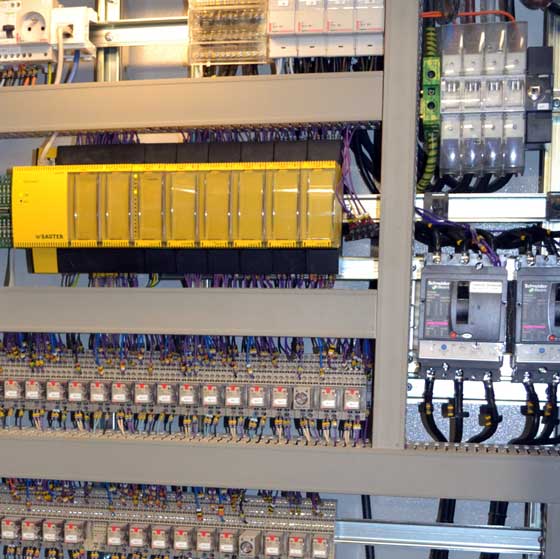

Devices

Industrial information and management systems like SCADA and Telemetry systems communicate directly with PLC subsystems. Historically, many different manufacturers have produced entire ranges of their own communication equipment with varying degrees of specialization. Today, however, manufacturers are orienting their PLC ranges towards high-level protocols offering numerous open, scalable and non-proprietary services (auto-discovery, notification, alarms, etc.).