Delivering performance

At Codra, we are committed to working alongside you on a daily basis to tackle the challenges of Industry 4.0 and Smart Cities. Our innovation strategy, together with a resolutely human and collective approach, leads us today to offer you the best in SCADA and technical and scientific engineering.

Our Mission:

Because we want to play an active role in the world around us by making our work count for as many people as we possibly can, Codra will place all its expertise and know-how in industrial computing at your service to support you in the innovative transformation and operation of your facilities.

To do this, we have set ourselves a twofold objective: to meet as many of your needs as possible with our Panorama software suite and, where appropriate, to support you on any highly sophisticated requirements through bespoke solutions.

We are here to help you push back your limits, so let’s make the difference together!

Our offer

Working hand in hand with you and being committed to your goals, our teams will provide you with the answers you need in one of two ways:

For projects relating to SCADA, telemetry, FM / BMS, BIM for operations, security hypervision, energy management, etc., opt for the Panorama software suite

Panorama Suite Platform

Panorama Department

For industrial, scientific and technical computing aspects, opt for our bespoke software engineering services.

Software Engineering

Engineering Department

Performance analysis, scheduling, quality management, traceability, ... choose COOX MES software

COOX Software

MES DepartmentNews & Resources

Technical focus pieces, articles, customer cases, definitions, videos, webinars… Find all our news and helpful resources.

Panorama obtains BACnet BTL certification

Take advantage of a proactive approach to the risks of non-compliance and effectively manage your building.

NIS 2 and SCADA: time to get compliant

The European NIS 2 directive will have a significant impact on businesses and public authorities in France. What impact will it have on your business and how can your teams prepare for it?

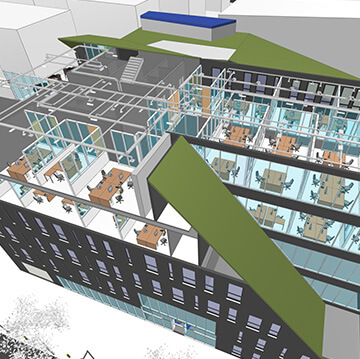

BIM, a precious ally for SCADA

With BIM For Operations, Panorama has decided to put BIM at the heart of its operations.

Codra exhibits at BIM World 2024 in Paris, France

Codra will be on stand C38 to present its Panorama real-time BIM Operation platform.

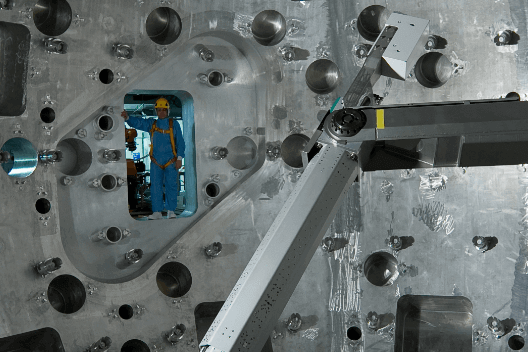

Codra exhibits at Global Industrie 2024 in Paris

A 100% made in france offer to meet the objectives of a low-carbon industry

A project to develop? A simple question to ask us?

Our teams are available to give you a demonstration or simply answer your questions!